A Biased View of 24hr Media

A Biased View of 24hr Media

Blog Article

Indicators on 24hr Media You Should Know

Table of ContentsAn Unbiased View of 24hr MediaGetting The 24hr Media To Work3 Simple Techniques For 24hr MediaThe smart Trick of 24hr Media That Nobody is DiscussingAll About 24hr Media

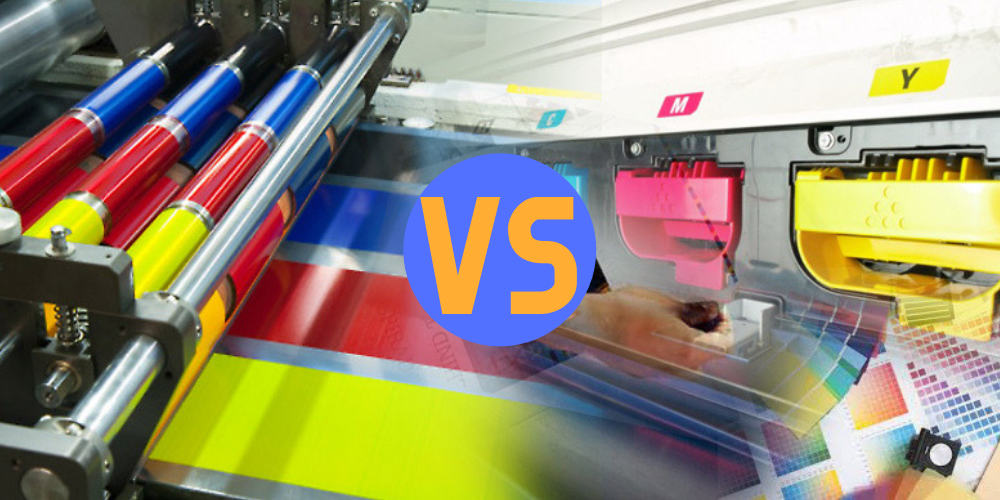

Offset, gravure printing and flexography are the most common sorts of conventional printing in the packaging space and each includes transferring the picture from a plate to the surface. To do this, first the plate requires to be produced, and it is the production of these plates that require time, and set you back cash.According to PMMI, digital printing allows brand names and suppliers to respond swiftly to consumer demands while improving the supply chain, reducing warehousing cost and waste, and enjoying faster time to market. That all audios great, yet exactly how does this technology do all that? The major differentiator of these technologies is that there are no set up charges and no plates with electronic printing.

According to Wikipedia, the best difference between digital printing and conventional methods such as lithography, flexography, gravure, or letterpress is that there is no need to replace printing plates in digital printing, whereas in these analog printing techniques the plates are consistently replaced. This causes quicker turn-around time and lowers expense when making use of digital printing.

Digital printing is extremely flexible, so it's simple to make modifications to the plan style promptly. It all goes back to the plates.

Some Known Facts About 24hr Media.

Extra stock can mean even more waste later on. With conventional printing methods, short-run printing is simply not possible. Since a terrific layout can make or break your product, digital printing constantly creates top quality, clear and colorful graphics each time. Digital printing on versatile pouches includes the brilliant, vibrant, and precise graphics that almost bid customers to connect and touch them.

Filling ... Are you aware of the benefits of electronic printing? Keep reading to recognize when electronic printing can be the best possible option for your service. Do you know why electronic printing has become the favorite option of some companies? Both balanced out and electronic printing have their location in the printing industry.

In this article, we will certainly review the advantages of electronic printing to assist you better comprehend if electronic printing is simply what you require. Put simply - digital printing prints product straight onto the paper. It gets rid of some actions required in countered printing, like developing metal plates. Inkjet printers use tiny nozzles to spray droplets of ink onto the substratum.

Fascination About 24hr Media

As digital printing regularly evolves, it supplies much more opportunities and greater outcome high quality everyday. Sometimes, the print high quality can be as high regarding offset printing. As years pass, electronic print is ending up being much more Related Site easily accessible, with boosted rate and high quality. This is just the factor printing business are including electronic printing to their offer.

For countered printing, if any blunder goes undetected before producing home plates, there will be a high cost of developing a brand-new one. With electronic printing, this is not the case (Large Format Printing). Everybody always hopes there will certainly be no errors, recognizing the cost of remedying them if they happen is always a good idea.

This indicates every piece will certainly look the same, so the opportunity you will certainly need to discard any of them due to disparities is low. Also, because a proofing sample is published on the same device as the item itself, shade proofing is very accurate. Any kind of issues with color will certainly be noticeable on the evidence, and hence it will be feasible to alter it before publishing the whole run.

The Buzz on 24hr Media

Digital printing, on the various other hand, calls for marginal setup. There are less pre-press procedures, so the first setup time is considerably decreased. Consequently, turn-around is noticeably much faster. Your order can be refined as quickly as you send it. This is terrific when you remain in a hurry to obtain your printed products.

This implies more requests for digital on-demand print manufacturing. Every client values a customized message. Cost-efficient, smaller batches allow businesses to tailor each order.

Digital printing is the perfect option for variable data printing, like customized codes and addresses on straight mail. With electronic printing, it is much less problematic to make last-minute adjustments to your layout. In some cases the very best type of interaction is not electronic. In these situations, counting on electronic printing can ensure these orders have a very little environmental influence.

A Biased View of 24hr Media

There is additionally no need to clean up home plates after printing. The benefits of electronic printing consist of that there is no waste from added or remaining ink, paper, or chemicals since just what's required obtains published. - for very brief runs, electronic printing is the way to go, undoubtedly.

Gone are the days of complex setups and long turn-around times - digital printing has actually changed the print market. The printing globe has come a long way since the days of Gutenberg's printing machine. The brand-new typical is streamlined processes and economical options for publishing onto virtually anything you can consider.

Report this page